In the world of heavy-duty trucking, your semi truck must perform well and stand the test of time. One of its most important, yet maybe one of the most unnoticed, components is the fuel filter. The fuel filter primarily maintains the fuel clean and devoid of harmful contaminations that can cause reduced engine performance and efficiency. This ultimate guide aims to dissect semi-truck-rated fuel filter specifications, so you can gain precious knowledge that will enhance the performance of your truck. When you know how these components work, you can make knowledgeable decisions on maintenance and reduce operating costs.

Within the ocean of knowledge regarding fuel filtration, it is important not just to dwell upon specifications but also to pay attention to performance metrics that create a clear divide between quality filters and the substandard kind. A major concern to be investigated is the importance of getting filters from reputed manufacturers, like those of a good Semi Truck Fuel Filter Factory. Choosing a good factory would ensure that you obtain filters conforming to industry standards, giving you maximum confidence in their performance. Join us in taking a look at some of the main specifications and performance metrics that will give you the foresight to select a semi truck filter that best serves your interests.

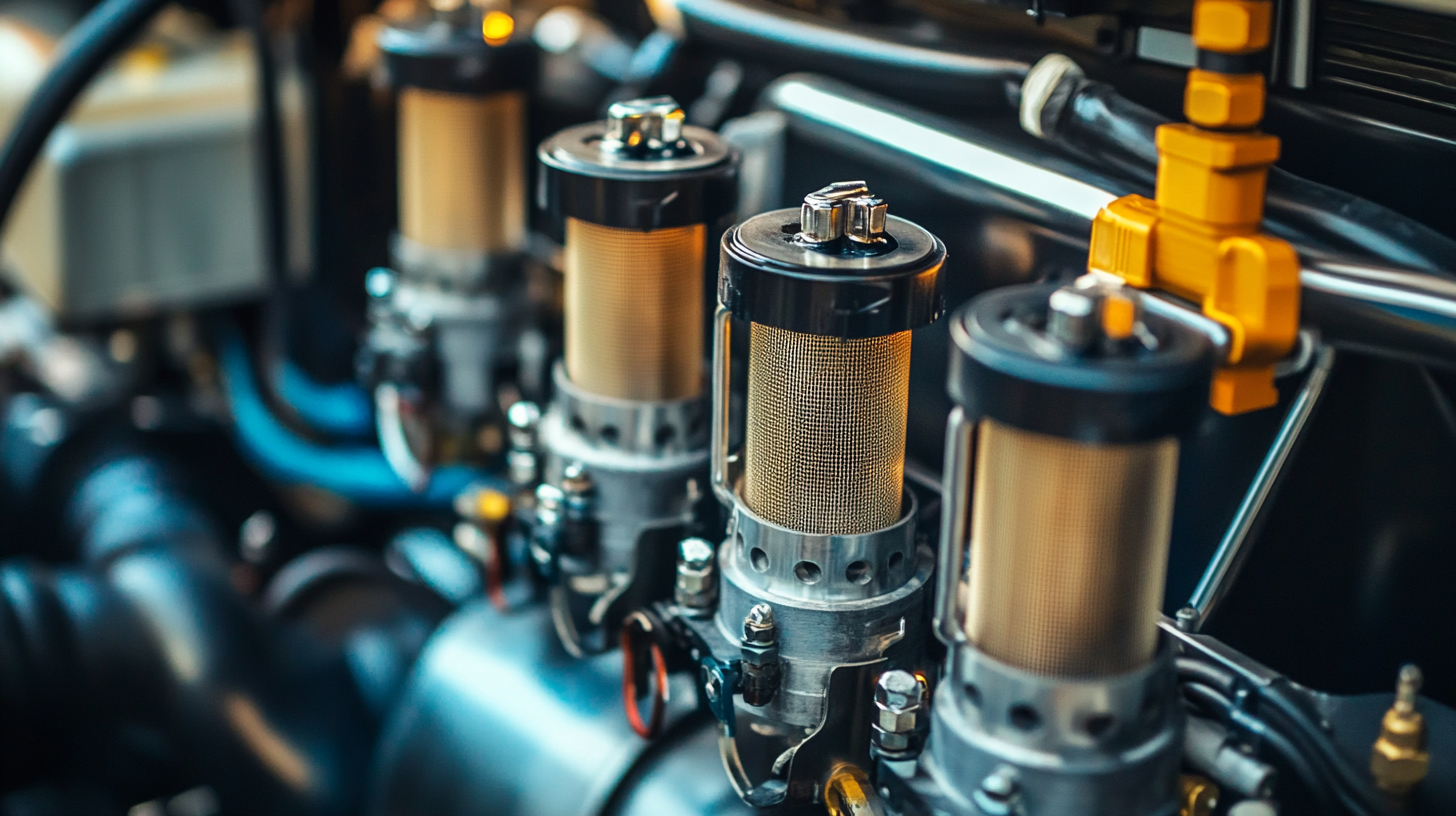

The vital role of fuel filters cannot be overstated concerning the performance and longevity of semi trucks, especially when fuel quality may differ on account of many external factors. Fuel filters serve to understand all existing problems on the engine, which could include power loss and poor fuel consumption. The result of a clean and effective fuel filter is that it prevents many impurities and contaminants from reaching the engine, which is very important in making the engine run at optimal performance. If neglected, fuel filters can lead to blockage in the engine, a decrease in efficiency, and arguably more frequent breakdowns, all of which compromise the reliability of the truck operation. Current atmospheric development with ever-increasing prices of fuel and the growing sophistication in automotive technology emphasizes the performance indicators, most especially regarding fuel filtration. Fleet operators are urged to put regular checks and the changing of filters in perspective, just to enhance performance and reduce liability in engine failures. With an increasing market demand in the industry for efficient fuel systems, specification knowledge becomes essential in building a maintenance strategy for smooth operation over time and cost savings. Considering future trends toward alternative fuel systems such as compressed natural gas will always mean having high-quality filters for fuel systems to protect the engine from contaminants and achieve high fuel efficiency.

While the specifications for the fuel filter are critical when selecting the fuel filter for semis to optimize performance and contingent reliability, the fuel filter is an important component that prevents contaminants from reaching an engine by supplying cleaner fuel for combustion and maintaining the engine efficiency in the process. Filter micron rating, flow rate, and service life are some of the most important specifications.

A lower micron rating indicates that it can catch smaller particles than those with higher ratings; the rated size typically ranges from 2 to 30 microns. For example, studies show that although it's not perfect at filtering particulates down to about 10 microns, it has the capability of clogging most debris without material restrictions on flow. The flow rate, which must meet or exceed the requirement of your semi truck, may vary based on the engine and the type of fuel it uses. The average flow rate for most diesel engines ranges from about 100 to 150 gallons per hour at a minimum level.

Another important specification deals with fuel filter service life. The average lifespan with good-quality filters is typically between 10,000 and 20,000 miles, depending on driving conditions and some maintenance practices. Regularly scheduled replacements are necessary to prevent clogging that causes engine performance problems. With new electric semi trucks being developed that change the status quo, fuel filtration is still relevant for diesel vehicles because of the inevitable rise of electric trucks in the industry.

With manufacturers deploying their new technologies-such as automatic tire inflation systems-it is evident the sands of time are shifting in the marketplace. Specifications and metrics will keep evolving as they guarantee efficiency and performance thereby important for the operators to keep up-to-date with the best practices in fuel filter selection and maintenance for their semi trucks.

Without a doubt, engine efficiency and longevity are key considerations when applying optimal performance for fuel filters in semi trucks. Proper filtration can improve engine performance by as much as 15%, as stated by the American Trucking Associations (ATA); this affirms that you should be mindful of the proper specification for the fuel filter for this purpose.

Filtration efficiency is one such parameter. This refers to the filter's ability to remove unwanted contaminants from the fuel. A filter that provides greater than 98% removal efficiency will greatly reduce wear on engine parts due to the removal of particles that would cause damage or detrimental inefficiencies. Beyond this, we also need to consider the micron rating of the fuel filter; typically, filters rate from 2 to 30 microns, with lower being better but requiring more frequent changes.

Dirt-holding capacity is yet another important yardstick. This relates to how much contaminant a filter can possibly hold before it calls for change-out of the filter itself. It is reported that filters with high dirt-holding capacities can result in extended service intervals, thus reducing maintenance costs and downtime. Pressure drop across the filter is another critical consideration: minimally so that optimal fuel flow is maintained, avoiding potential cavitation in the fuel system. These performance metrics ensure that these semi trucks work efficiently, so it will be reliable and help save on operational costs.

To summarize: The fuel filtration system is a big player in semi trucks when it comes to sustaining engine performance and longevity. But common problems are faced by many operators, hindering the effectiveness of these systems. One of which is an adequate presence of water and contaminants in diesel fuel, which in turn encourages microbial growth and corrosion; all aspects leading to a more compromised fuel but capable of inflicting severe damage on engine components if not filtered well.

The second challenge faced is the inconsistent quality of fuel drivers receive. Fuel from different sources may contain different concentrations of impurities, demanding adaptive and rugged filtration systems. Also, fuel filter performance will steadily decline with time, especially where monitoring and replacement are not practiced. This calls for regular maintenance to give semi trucks a fighting chance for their filters to operate under the conditions specific to their environment.

Lastly, the design and capacity of the filtration system should be considered. Operators commonly contend with space limitation issues on their trucks, calling for compact solutions with high filtration performance. Finding a balance between filter size and efficiency is paramount, as inefficient filtration systems can lead to early wear and higher operating costs. A thorough response to these challenges ensures an easier run and mitigates the risk for unexpected breakdowns on the road.

Fuel filter maintenance in semi trucks is required for the performance and longevity of the engine. An effective fuel filter is clean and efficient. A dirty fuel filter allows contaminants to enter the engine, which affects performance, increases fuel consumption and damages it over the years. Replacement and regular checks are essential practices for any truck owner/operator who wants their equipment to perform optimally.

According to the manufacturer's recommendations on interval change, a good fuel filter is one which keeps the manufacturer's replacement intervals. Change anywhere from 10,000 miles to 20,000 miles depending on the particular fuel used and operating conditions. A fuel filter issue may be shown by an engine running poorly or starting difficulty. Regular visual inspections can also bring to light leaks or blockages.

Replace the fuel filter with filters that meet or exceed OEM specifications because most substandard filters cause more problems downstream. In addition, proper priming is imperative while installing the new filter to ensure sufficient fuel flow to the engine right after replacement. Following these best practices improves the efficiency of the truck and prolongs the time the vehicle can spend on the road giving more time to predictable and economical performance.

Fuel filters are essential for the performance and longevity of semi trucks as they prevent impurities and contaminants from reaching the engine, which helps maintain optimal performance and prevents engine issues.

Neglecting fuel filters can lead to engine blockages, decreased efficiency, and more frequent breakdowns, ultimately affecting the reliability and operational performance of a truck.

Fleet operators are encouraged to regularly inspect and replace fuel filters to enhance performance and mitigate risks associated with engine failure.

Operators often face challenges such as water and contaminants in diesel fuel, variability in fuel quality, and the degradation of filter performance over time.

Fuel obtained from different sources may contain varying levels of impurities, necessitating filtration systems that are adaptable and robust to maintain engine performance.

Operators must consider space constraints and ensure that the filtration system provides high performance while being compact enough to fit in the available space in the trucks.

Inadequate fuel filtration can lead to premature wear of engine components and increased operating costs, which may result in unexpected breakdowns.

Regular maintenance is crucial to ensure that semi trucks are equipped with filters that meet the specific requirements for their operating environment and to prevent engine damage.

The integration of high-quality fuel filters will remain essential for new alternative fuel systems, like compressed natural gas (CNG), to protect the engine from contaminants and achieve optimal fuel efficiency.

Paying attention to fuel filtration performance can help enhance operational reliability, save costs, and mitigate risks associated with engine failures in semi trucks.